Deskripsi Produk:

Fused Aluminum Oxide adalah bahan abrasif yang sangat serbaguna dan tahan lama yang dikenal karena kekerasannya yang luar biasa dan kinerja unggul dalam berbagai aplikasi industri. Dengan peringkat kekerasan Mohs 9, Fused Aluminium Oxide termasuk di antara zat terkeras, menjadikannya pilihan ideal untuk media peledakan, penggilingan, pemolesan, dan tugas persiapan permukaan. Kekerasannya yang luar biasa memastikan pelepasan material yang efisien sambil mempertahankan bentuk dan integritasnya, yang mengarah pada hasil yang konsisten dan andal.

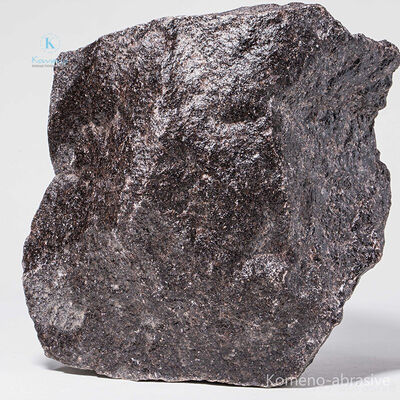

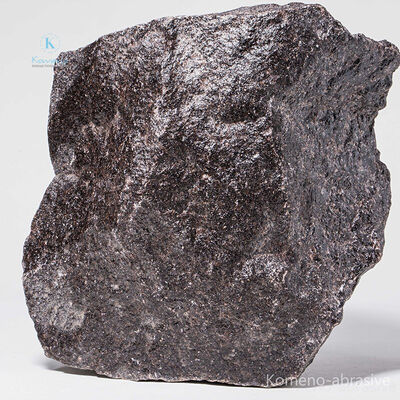

Salah satu karakteristik khas Fused Aluminium Oxide adalah warnanya, yang berkisar dari putih hingga abu-abu. Pewarnaan alami ini adalah hasil dari proses pembuatannya yang unik, di mana alumina kemurnian tinggi dilebur dan difusikan pada suhu yang sangat tinggi. Produk yang dihasilkan menunjukkan stabilitas, ketangguhan, dan ketahanan yang sangat baik terhadap keausan, sehingga cocok untuk lingkungan industri yang menuntut. Warna yang konsisten juga membantu dalam mengidentifikasi kelas dan kualitas abrasif, memastikan pengguna dapat memilih bahan yang sempurna untuk kebutuhan spesifik mereka.

Selain kekerasannya yang mengesankan, Fused Aluminum Oxide memiliki resistivitas listrik yang tinggi. Sifat ini menjadikannya bahan yang sangat baik untuk aplikasi di mana isolasi listrik sangat penting. Resistivitas listrik yang tinggi dari Fused Aluminium Oxide membantu mencegah konduktivitas listrik, menjadikannya aman dan andal untuk digunakan dalam peralatan presisi, komponen elektronik, dan aplikasi sensitif lainnya. Kombinasi kekerasan dan isolasi listrik ini membedakan Fused Aluminum Oxide dari bahan abrasif lainnya, menawarkan perpaduan unik antara kinerja dan keamanan.

Sebagai media peledakan, Fused Aluminium Oxide unggul dalam persiapan dan pembersihan permukaan. Ketangguhannya memungkinkannya untuk secara efektif menghilangkan lapisan, karat, dan kontaminan dari permukaan logam tanpa menyebabkan kerusakan atau deformasi yang berlebihan. Hal ini menjadikannya bahan yang sangat diperlukan dalam industri seperti dirgantara, otomotif, pembuatan kapal, dan konstruksi, di mana kualitas dan persiapan permukaan sangat penting untuk keberhasilan proses manufaktur atau penyelesaian selanjutnya. Butiran tajam dan bersudut dari Fused Aluminum Oxide memastikan aksi pemotongan yang agresif, yang mengarah pada operasi peledakan yang lebih cepat dan lebih efisien.

Selain itu, kekerasan dan daya tahan tinggi dari Fused Aluminium Oxide berkontribusi pada umur panjangnya sebagai bahan abrasif. Tidak seperti bahan yang lebih lunak yang cepat rusak, Fused Aluminum Oxide mempertahankan sifat abrasifnya melalui penggunaan yang diperpanjang, mengurangi frekuensi penggantian media dan menurunkan biaya operasional secara keseluruhan. Daya tahan ini juga meminimalkan pembentukan debu selama peledakan, menciptakan lingkungan kerja yang lebih bersih dan meningkatkan keselamatan bagi operator.

Fused Aluminum Oxide juga banyak digunakan dalam aplikasi penggilingan dan pemolesan. Kekerasannya yang unggul memungkinkan pelepasan material yang presisi dan konsisten, menjadikannya cocok untuk finishing logam, keramik, kaca, dan bahan keras lainnya. Butiran abrasif memberikan keseimbangan antara efisiensi pemotongan dan kualitas hasil akhir permukaan, memastikan hasil yang halus dan bebas cacat. Selain itu, kelembaman kimianya dan stabilitas termalnya membuatnya tahan terhadap kontaminasi dan degradasi selama proses bersuhu tinggi.

Singkatnya, Fused Aluminium Oxide menonjol sebagai bahan abrasif utama yang menggabungkan kekerasan Mohs 9, warna putih hingga abu-abu yang khas, resistivitas listrik yang tinggi, dan kinerja yang sangat baik sebagai media peledakan. Kombinasi unik dari sifat fisik dan kimianya menjadikannya sumber daya yang tak ternilai dalam berbagai aplikasi industri. Baik digunakan untuk peledakan, penggilingan, pemolesan, atau persiapan permukaan, Fused Aluminum Oxide memberikan daya tahan, efisiensi, dan keandalan yang tak tertandingi, memenuhi tuntutan ketat dari proses manufaktur dan pemeliharaan modern.

Fitur:

-

Nama Produk: Fused Aluminum Oxide

-

Kekerasan: 9 Mohs

-

Warna: Putih hingga Abu-abu

-

Jenis: Media Peledakan

-

Ideal untuk Produk Pengecoran Presisi

-

Juga dikenal sebagai Fused Aluminum Oxides atau Fused Aluminium Oxide

-

Berisi Brown Corundum untuk meningkatkan daya tahan

Parameter Teknis:

|

Nama Produk

|

Fused Aluminum Oxide

|

|

Rumus Kimia

|

Al2O3

|

|

Kekerasan

|

9 Mohs

|

|

Penampilan

|

Bubuk Kristal Putih Hingga Abu-abu

|

|

Jenis

|

Media Peledakan

|

|

Ukuran Partikel

|

2-3mm

|

|

Bahan

|

Aluminum Oxide

|

|

Bahan Utama

|

Aluminum Oxide

|

|

Warna

|

Putih Hingga Abu-abu

|

|

Untuk

|

Produk Pengecoran Presisi

|

Aplikasi:

KMN Fused Aluminum Oxide, nomor model F, adalah bahan abrasif yang sangat serbaguna yang banyak digunakan dalam berbagai aplikasi industri karena kekerasannya yang luar biasa dan stabilitas kimianya. Disertifikasi dengan ISO 9001, produk ini menjamin kualitas dan keandalan yang konsisten untuk lingkungan yang menuntut. Dengan kekerasan 9 Mohs dan ukuran partikel mulai dari 2-3mm, Fused Alumina KMN sangat ideal untuk aplikasi yang membutuhkan kinerja abrasif yang tahan lama dan efisien.

Fused Alumina banyak digunakan dalam proses peledakan abrasif, penggilingan, pemolesan, dan pemotongan. Komposisi kimianya yang stabil membuatnya cocok untuk digunakan di lingkungan asam dan basa, memastikan umur panjang dan degradasi minimal selama pengoperasian. Hal ini membuat KMN Fused Aluminum Oxide sempurna untuk industri seperti fabrikasi logam, otomotif, dirgantara, dan konstruksi, di mana persiapan dan penyelesaian permukaan sangat penting.

Selain abrasif, Fused Alumina digunakan sebagai bahan tahan api karena titik lelehnya yang tinggi dan stabilitas termal yang sangat baik. Ini umumnya digunakan dalam lapisan tungku, furnitur kiln, dan aplikasi bersuhu tinggi lainnya, memberikan perlindungan dan daya tahan dalam kondisi ekstrem. Sifat kimia yang stabil dari KMN’s Fused Alumina juga membuatnya cocok untuk pembuatan keramik tahan aus dan alat potong, meningkatkan kinerja dan umur pakainya.

Kemampuan pasokan KMN adalah 30.000 ton per tahun, melayani permintaan industri skala besar. Kuantitas pesanan minimum adalah 5 ton, dengan harga yang dapat dinegosiasikan berdasarkan ukuran dan spesifikasi pesanan. Waktu pengiriman bervariasi sesuai dengan kuantitas yang dipesan, memastikan fleksibilitas dan pasokan tepat waktu untuk berbagai persyaratan proyek. Ketentuan pembayaran termasuk T/T dan L/C pada pandangan, membuat transaksi nyaman dan aman bagi pelanggan global.

Secara keseluruhan, KMN’s Fused Aluminum Oxide menawarkan sifat abrasif yang sangat baik, stabilitas kimia, dan ketahanan termal, menjadikannya pilihan yang disukai untuk berbagai kesempatan dan skenario aplikasi. Baik untuk peledakan abrasif, lapisan tahan api, atau pembuatan keramik berkinerja tinggi, produk Fused Alumina ini memenuhi tuntutan ketat industri modern sambil mempertahankan kualitas tinggi dan efektivitas biaya.

Kustomisasi:

KMN menawarkan layanan kustomisasi produk yang komprehensif untuk Fused Aluminium Oxide, juga dikenal sebagai Brown Corundum atau Fused Aluminum Oxides. Produk model F kami disertifikasi dengan ISO 9001, memastikan kualitas dan keandalan yang tinggi. Kami mengakomodasi kuantitas pesanan minimum mulai dari 5 TON, dengan harga yang dapat dinegosiasikan berdasarkan persyaratan spesifik Anda.

Waktu pengiriman untuk Fused Aluminum Oxide kami bervariasi sesuai dengan kuantitas pesanan, memungkinkan fleksibilitas untuk memenuhi jadwal proyek Anda. Ketentuan pembayaran termasuk T/T dan L/C pada pandangan, menyediakan opsi yang nyaman bagi klien kami. Kemampuan pasokan kami kuat, mampu mengirimkan hingga 30.000 ton per tahun untuk mendukung kebutuhan industri skala besar.

Dengan kekerasan 9 Mohs, produk Fused Aluminium Oxide kami menunjukkan daya tahan dan kinerja yang sangat baik. Mereka tersedia dalam warna mulai dari putih hingga abu-abu dan memiliki penampilan bubuk kristal putih hingga abu-abu. Selain itu, stabilitas kimia dari Brown Corundum kami memastikan tetap stabil di lingkungan asam dan basa, sehingga cocok untuk berbagai aplikasi.

Percayai KMN untuk solusi khusus dalam Fused Aluminum Oxides yang memenuhi spesifikasi dan standar kualitas Anda yang tepat.

FAQ:

Q1: Apa merek dan nomor model produk Fused Aluminum Oxide?

A1: Nama mereknya adalah KMN dan nomor modelnya adalah F.

Q2: Apakah produk Fused Aluminum Oxide bersertifikasi?

A2: Ya, itu disertifikasi dengan ISO 9001.

Q3: Berapa kuantitas pesanan minimum untuk produk ini?

A3: Kuantitas pesanan minimum adalah 5 ton.

Q4: Bagaimana harga ditentukan untuk Fused Aluminum Oxide?

A4: Harga dapat dinegosiasikan tergantung pada kuantitas pesanan dan faktor lainnya.

Q5: Apa ketentuan pembayaran dan waktu pengiriman untuk produk tersebut?

A5: Ketentuan pembayaran adalah T/T atau L/C pada pandangan. Waktu pengiriman tergantung pada kuantitas pesanan.

Q6: Apa kemampuan pasokan KMN untuk Fused Aluminum Oxide?

A6: KMN memiliki kemampuan pasokan 30.000 ton per tahun.

Pesan Anda harus antara 20-3.000 karakter!

Pesan Anda harus antara 20-3.000 karakter! Silakan periksa email Anda!

Silakan periksa email Anda!  Pesan Anda harus antara 20-3.000 karakter!

Pesan Anda harus antara 20-3.000 karakter! Silakan periksa email Anda!

Silakan periksa email Anda!